Tube Bending Technology

JD Laser Inc. has expanded its tubing equipment to include an all-electric, combined right and left hand CNC tube bender with a machine capacity of 2” diameter x .065 wall.Tube Bending Technology

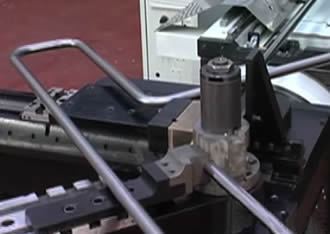

JD Laser Inc. has expanded its tubing equipment to include an all-electric, combined right and left hand CNC tube bender with a machine capacity of 2” diameter x .065 wall.

This multi-tool stack tube bender can perform, in automatic cycle to the same tube, a combination of left and right hand bends, conventional and variable radius (push) bends, multi-radius bends, tight radius bends (e.g., 1-D) and compound bends, i.e., with little if any straight between bends.

The precise “controllability” of the 12 axis movements is ensured by the inherent accuracy of the all-electric drives. The highly refined visual 3D-Graphic software automatically selects the bending program parameters to optimize cycle times and to deskill the setting process. As a result components are produced consistently at the highest possible output and quality, right-first-time with no scrap, repeatable batch to batch, and without reliance on operator expertise.

What’s more with all the axis movements set automatically a job changeover can typically be completed in 2 to 3 minutes, enabling short batches to be managed as efficiently as high volume work.