2D Laser Technology

We offer in-house programming, short lead-times and prototyping.Using 2D Laser Technology

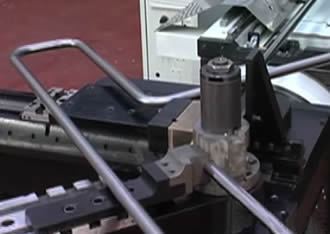

Our Gemini series Amada system handles sheet sizes up to 5′ x 10′ and is capable of cutting up to 0.750″ mild steel, 0.375″ stainless steel and 0.250″ aluminum.

Our Amada system is able to produce smooth, continuous edges on our parts. Some other capabilities of the Amada system include: etching, part marking, edge quality, sprocket cutting and saw blade edge cutting, as well as the ability to work with vinyl-coated stainless and pre-coated Paintloc materials.

We have a high-speed shuttle table that provides faster loading and unloading capabilities. The tower has 10 shelves, each holding up to a maximum of 5000 pounds with sheet thickness up to 0.75″. The tower is fully programmable and allows for partially processed products to be interrupted and returned to the tower to be processed later, if need be.

Our “New in 2009″ 4020 Gemini Amada is a two-dimensional flat sheet-cutting machine that handles sheet sizes up to 6′ x 13′ and capable of cutting material thicknesses’ up to .750″ mild steel, .375″ stainless steel and .250″ aluminum.

Our Hankwang Laser can handle sheet sizes up to 5′ x 10′ and is capable of cutting up to 0.750″ mild steel, 0.375″ stainless steel, and 0.250” aluminum.

All of our flat laser systems have shuttle tables which allow us to load/unload a new sheet for production while the laser is processing the current sheet. The second table is set up to automatically switch as soon as the first table has completed processing, allowing for a smooth transition and continuous work flow. We offer in-house programming, short lead-times and prototyping.